3D digital factory are widely used in petroleum, chemical,coal, fire, electricity, receiving station and other relevant industries.Realize full life cycle data management of plant and stations, dynamic management of safety production, centralized control of daily business, and enhance enterprise’s ability to resist risk.

Value to You:

Full life cycle equipmentdata collection and database construction to provide the enterprise withaccurate asset information.

Visualized business training to raise enterprise’s safety production level.

High degree integration ofbusiness process to realize enterprise’s “integrated operation”

On basis of full life cycle to realize construction of integrated intelligent plant.

Main features:

Full life cycle data management

Based on the mature data model, conduct organization modeling and data maintenance for full life cycle drawings, images, videos, operation, geography, property and etc. of the plant.

Integrated management of daily business

Realize integrated platform management of information, such as planning evaluation, plant design, construction process, operation and maintenance and security management.

Fusion of multiple technologies to achieve integrated management

Realize integrated application of pipeline business by two or three - dimensional integration technology with independent intellectual property rights, big data processing technology, mobile office technology, CAD, workflow technology.

Open system architecture conducive for expansion

Based on SOA system architecture, adopt service-oriented application mode to satisfy integration and expansion ofcompany’s multiple business requirements.

Optimal solution:

Digital technology service:

Integral data acquisition service

Measure and gather the data of building, equipment, ancillary facilities and underground pipeline in the plant, as well as the data in construction period.

It’s the important basis for realizing plant integrity management to build integral database management, prevent data from losing during construction or operation and enhance the security and integrity of data.

Visualized construction management

Combined with DOM and DEM data, the company builds 3D fundamental geographic information platform, simulation model of equipment and facilities as well as progress report of construction process. Provide spatial query, positioning, measurement, analysis and other functions.

Management system of plant factory Asset management system

Make classification management for equipment in the plant, and inventory of spare parts, to realize electron flow management of spare parts, while achieving the equipment management,maintenance management, maintenance scheduling and management and other functionsin a 3D scene.

Visualized management system Performance monitoring

Visualized presentation of real-timedata of SCADA and DCS: temperature monitoring and alarm, pressure monitoring andwarning, flow monitoring and alarm, liquid level monitoring alarming, switch status monitoring and alarming.

Visualized training

Employee safety education training: to display emergency evacuation passage way and security response process.

Equipment Mechanism training: to display internal section of the main equipment in the plant.

Equipment disassembly & assembly training: to make dynamic disassembly and assembly of the core equipment in the plant.

Technological process training: to display the main technological process, especially switches of the valves and current direction of pipeline medium.

Trends of production personnel

Plan the activities area, track production personnel’s position, grasp the actual distribution and track of plant personnel, alarm the personnel in unauthorized area or overtime, in order to enhance the security ofthe workplace and self-protection ability of the personnel.

Industrial video monitoring

Conducting real-time monitoring of theplant in a 3D visualized scene permits users knowing all cameras location at aglance, as well as directly monitoring and recording the work security condition

Visualized Electronic Inspection

Formulate inspection business procedures, conduct visualized tracking of inspection in a 3D scene, and realize digitalized, visualized and real-time management forline inspector.

Real-time monitoring to inspect the work state of line inspector;

Trace playback to check pass rate of line patrol;

Make various statistical reports in accordance as required, such as violation event reports, report of line patrol pass rate and so on.

Daily security management

Manage major hazards and hidden dangers in or around the plant, monitor security condition of dangerous source objects,mark hidden dangers in 3D scene, provide various functions of query, display, and statistic analysis, as well as support visualized monitoring management of hidden danger's whole process of recording, rectifying and vivificating.

Emergency management

Administrating company’s emergency plan, making accident stimulated drill, and emergency coordination command to provide integrated display platform can enhance company’s emergency rescue efficiency. Combined with 3D geographic information system, it can display the emergency equipment resources, surrounding rescue resources, refuge and populous place, etc. in the 3D scene, which is convenient for enterprise to rapidly deploy the emergence resources in face of accidents.

Document Management system

Realize centralized administration and storage of various electronic information materials produced throughout plant’s full life cycle (including electronic document, audio-video materials, electronic drawings, testing report and other information). Have the ability to interact with equipment and project and provide hierarchical view access and other functions. Make sure the large amount of electrical documents produced during construction can be stored and read effectively and provide support for company’s operation.

Station Integrity Assessment

Based on attribute data, running state data, maintenance data, and historical failure data, it realizes risk management of equipment with various characteristic; based on asset integrity management technology, it applies the deep integral management of risk to the key parts of the equipment.

It is a package of integrated solutions provided for the field of oil and gas transmission, which deal with the application management for data acquisition, database foundation with data model and integration of data center based on the full life cycle of business. The solution covers the integrated service platform and technical supporting system of data center, which will be applied in the acquisition, transmission, storage and integrated application of dynamic and static mass data produced during the construction of oil and gas transportation business and the productive process.

It's Values for You

Main Characteristics:

Scheme Contents

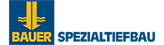

a) General framework of data center

With the help of technologies such as 2D and 3D GIS, cloud computing and intelligent analysis, it achieves the acquisition controlling, transmission and storage ofdata during the business process, and realizes the comprehensive analysis and intelligent management of elaboration, diagnosis and sharing.

b) Technical support

Service of data standard and specification construction

Covering the full life cycle and business process, the data standard and specification system proposes requirements in management and technology for directing the data acquisitionand database foundation based on the full life cycle.

Service of data center construction in the full life cycle

Set up private cloud platform for enterprises, which will be used as the support for establishing large enterprise data center based on infrastructures. Also, by regarding the full life cycle data of pipeline as a subject, a database is founded to realizing the centralized storage, transportation, exchange and unified informatization management of pipelines within total asset, overall process and full-service from planning to scrapping.

Construction data acquisition service

It provides services such as measuring at engineering control points, measuring in the construction process,annotation of emergency resources and annotation of surroundings and provides accurate basic data and environmental data for pipelines.

c) Integrated application platform

The integrated application platform provides services such as unified and overall data management, data access and business process management for large data centers.

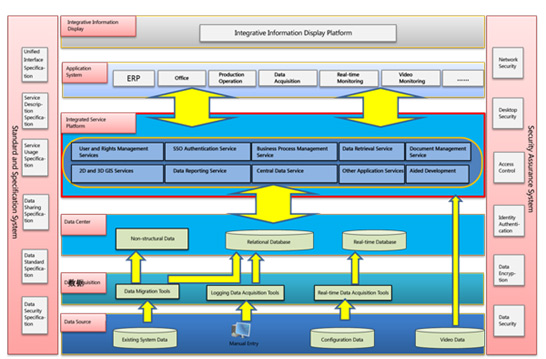

Construction thoughts of underground pipe gallery based on full life cycle management

Establish a full lifecycle informatization standard system of the underground pipegallery on a G-UIM basis and establish a data management and application service platform of unified standards, clear relations and consistent data to collect, hand over and share data in every phase such as survey & engineering, construction, operational maintenance of the underground pipegallery, for the purposes of visualizing the engineering analysis, elaborating the constructional management and intelligentizing the operational maintenance.

Application programming of intelligent underground pipe gallery

Application architecture:- adopt unified 2D & 3D platforms and unified data standards, and establish a full lifecycle data center and applications for the underground pipe gallery, so as to output data for other units (pipe network access units or governmentsand relevant departments) on the basis of management requirement according tot he purview.

Construction for data center of underground pipe gallery

Planning and design

a) Quality management & control

Integrate the programme of the underground pipe gallery, design results, environmental assessment results, outsourcing work results and visualization of the basic geographic information results into a unified platform.

Establish a unified data center for the underground pipe gallery with the purpose of achieving the unified management of data;

Visualization inspection of planning programming results to assist in promoting the programming quality and avoiding the site changes during construction process

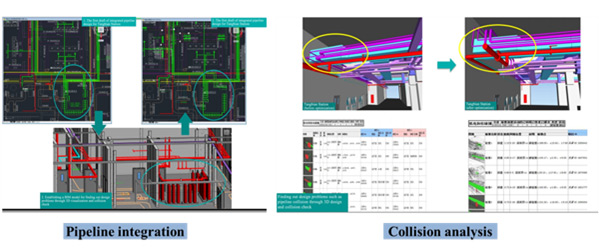

b) G-UIMmodel management (collaborative engineering)

Engineering management & control – construction drawing engineering management & control

Construction process management for underground pipe gallery

Set up an engineering construction integrated management platform for providing the project management department, the supervision organization, the contractors and the construction units with a unified office environment, and for integrating engineering results data, construction technology data and business management data on the basis of functional modules to deploy such as information issue, resource share, documentation exchange, collaborative office, discipline management, data collection, engineering change, completion management, 2D & 3Dvisualization management & control as well as comprehensive display in the platform and the data center, thereby providing highly efficient measures for the five main factors management and external resource management of the project.

Visualized management & control for construction process

Load the engineering result data, the construction basic data (including thegeographic information data) and the business management data into a unified pipe gallery model, and to display them through visualization on the 2D &3D visualization platform to form “one map” of engineering data, there by achieving the global monitoring and multi-dimensional analysis of each core field of the engineering project and supporting applications in respect of the real-time display and comprehensive comparison of construction scheme and construction progress, warning of engineering and construction data deviations, QHSE risk identification and early-warning, or the like.